Financing the transition can be considered at two levels: of the firm/institution and across supply chains. Although the firm/institution is typically taken as the unit of analysis, looking across supply chains is important. The costs of reducing food waste may be borne at one stage of the supply chain, while the benefits may accrue in another stage. Alternately, the costs may occur upfront, with the benefits, if any, resulting later. Finally, the reductions (and costs and benefits) may only result from collaboration among different supply chain actors. For example, farmers may seek to reduce waste by improving their storage facilities; however, if they do not have adequate market access or receive a suitable price for their additional crop, it may not be worth the investment (Rutten, 2013).

A key feature of transition financing is not leaving the burden on government waste management programs. There is some evidence that the failure to follow the kind of food waste framework proposed here shifts additional costs onto governments because there is insufficient focus on food waste prevention at the firm and supply chain level and too much on diversion once waste has been generated, a responsibility typically of municipal and provincial government (see the case of Nova Scotia in Meikle, 2018). Shifting to prevention means moving costs (and revenues) more to firms and supply chains.

Firms and institutions

The policy and programme changes proposed here will, in many cases, impose new upfront costs on firms and institutions. Case studies suggest, however, that food waste reductions can, in many instances, produce substantial operational savings, or generate new revenue streams, especially if the waste reductions are captured early in supply chains (Gooch & Felfel, 2014). Gooch and Felfel (2014, p. 5) remarked “How many items must a retailer, manufacturer, distributor, or farmer sell to cover the costs borne from each item wasted or lost? To our surprise, this is a question that businesses typically cannot answer.” WRAP U.K. (2014) estimated that the average firm could reduce operating costs by 15 to 20% and increase profitability by five to eleven percent. A full regulatory impact analysis is beyond the scope of this paper, but we provide here some scenarios that suggest what might be feasible. Unfortunately, most studies have not taken account of O’Brien’s (2013) warning regarding surplus accumulation so some of the revenue projections will be overestimates within our framework of analysis.

Uzea et al. (2014) summarized the experience of a Tim Hortons’ supplier that saved almost half a million dollars a year from a waste discharge reduction project, with corresponding significant savings in electricity, natural gas and water. The increased revenue for the plant also generated a substantial net increase in revenue for the government, in that the added taxes amounted to over $140,000. Government support to help identify the appropriate program for the firm to employ only amounted to $4000.

Working with Enviro-Stewards Consulting, Maple Leaf Foods had audits conducted on 33 manufacturing plants and claims to have saved $60-140,000 / facility with less than a year payback on investments (Enviro-Stewards, n.d.). Working with 50 food and beverage companies that are part of Provision Coalition, Enviro-stewards claims the equivalent of 15.4 million meals saved / year in food loss reduction, and firm savings of $11.4 million.

Augustana College, a small college of 2500 students in western Illinois, U.S., has figured out how to source a significant percentage of its food locally, send the food scraps back to those farms, and save money at the same time. Being in a semi-rural area has probably made it easier to set up these short supply-and-reuse chains.

Hospitals are receiving considerable attention because of the poor food quality and high waste levels. Hospital beds in Ontario cost about $1200 per day, but hospital food is only $6 to 12 per day. With labour and other costs, it comes to $30 to 35 per day (Wylie-Toal, 2013; Mintz, 2016).

In many cases, 40% of the food served is returned to the kitchen. The premise is that greater patient satisfaction with food reduces waste. Hospitals could save money by eliminating items that are infrequently eaten or portions that are too big, providing patient menu selection, buying only from suppliers who will take back the packaging, using better food forecasting and performing regular tray audits. Following these reduction efforts, there might also be savings on the disposal side as two-thirds of hospitals put food waste in the regular waste stream and do not segregate for composting or other possibilities (Mior, 2009).

It has been suggested that waste savings can finance the improvements in hospital food service. Let us suppose that waste is cut in half, to 20%, resulting in an additional $1.50 in food available for consumption. Though difficult to quantify, that $1.50 could have multiple positive impacts. According to one case example from a Toronto hospital, improving the food ingredients and quality of the food would increase costs within that $1.50 projected savings (Mintz, 2016). It could improve health status of patients who are eating more and better and potentially reduce time in hospital. It might mean a reduction in food procurement costs, if patients do not eat more, and the portion sizes are made more appropriate. The same amount of food would be spread over more patients, also making labour expenses more efficient. It appears though that in-house food preparation may be central to success and many hospitals rely on central commissaries. If the hospital has abandoned in house food preparation, it may not have the proper infrastructure (McGee, 2022). Some US hospitals are claiming that the food bill did not increase in their shift to better food because reduced food waste allowed them to improve their ingredients yet stay within existing budgets. Their increased expenses came from equipment improvements and paying more in salaries to skilled chefs (Carman, 2023)

Regarding waste disposal savings, approximately 17.3% of the hospital waste stream is organic waste, and non-hazardous waste disposal costs range from $71 to 116 per tonne (Ontario Hospital Association, n.d.). Ontario hospitals discarded an average of 0.22 to 0.67 kg of food and packaging waste per meal served (Strashok, Dale, Herbert, & Foon, 2010). Reducing this waste by half, however, only saves about $0.07 per day[1], because disposal costs are currently so low. With higher fees and ultimately a landfill ban, it becomes more feasible for waste disposal costs to finance food service improvements.

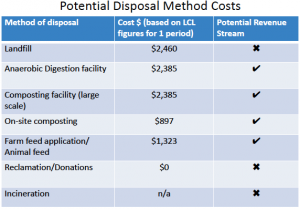

For food retailers, revenue from diversion of food waste to marketable products such as compost and biogas is another way of financing early stage transitions. See our estimates from research conducted on a major Canadian retailer.

Potential costs of different waste management methods for a major Canadian retailer (authors’ calculations from document analysis and interviews)

However, later stage reductions in food waste will shrink these revenues, so great care must be taken to properly scale revenue generation initiatives and avoid the surplus accumulation inclinations of firms as described by O’Brien (2013).

Across supply chains

WRAP U.K. claims their initiatives have resulted in a reduction of 670,000 tonnes of food waste throughout the U.K., saving £700 million for consumers and £20 million for governments in 2012. They estimate that every pound (£) invested in Love Food, Hate Waste saves £500 (WRAP U.K., n.d.). “Many big brands have embraced this agenda, recognizing the commercial benefit. Less waste means less cost” (Gooch et al., 2010, p. 8). In another government-supported initiative in Europe, between the Institute of Grocery Distribution (IGD) and Cranfield University, farmers and small businesses are encouraged to “Sell More, Waste Less” by going through and evaluating the entire value chain’s processes and performance in order to identify causes of food waste. The programme estimated that businesses are able to reduce their costs by 20% and increase their sales by 10% by adopting new ways of managing their value chains (Gooch et al., 2010).

Tupper and Whitebread (2011) conducted eight case studies on supply chain coordination and found a seven to one benefit to cost ratio, where the costs were largely the time spent on the project by the facilitator and the companies, and the benefits were company savings and avoided landfill taxes. Key coordination strategies included: regular meetings between suppliers and retailers; better forecasting; more precise ordering and more detailed order information and better ordering tools; changes to package design, size and colouring to facilitate communication between supplier, retailer and consumer; and pricing changes to move lower demand product.

It would appear, then, that many of the costs imposed by regulatory changes are recoverable, especially as waste disposal fees increase. How to finance demand-supply coordination requires thorough study, but given the way current Canadian marketing boards use levies on distribution or price setting powers, it would appear that many of these costs could be imposed on the market place as they are currently.

Endnotes:

[1] By some estimates, food packaging waste is about one-quarter by weight of food waste weight. So, let us presume that disposal costs $100 per tonne and $17 of that is food waste. The average hospital site in Ontario has 140 beds (31000 beds divided by 224 sites). We assume 0.45 kg per meal served is waste and 80% of that is food waste, so 0.36 kg per meal. Reducing food waste by one-half means reducing the weight to 0.18 kg per meal. We also assume 95% bed occupancy on any given day. Three meals per day x 140 beds x .95 x 0.18 kg = 71.2 kg per day in saved food waste.