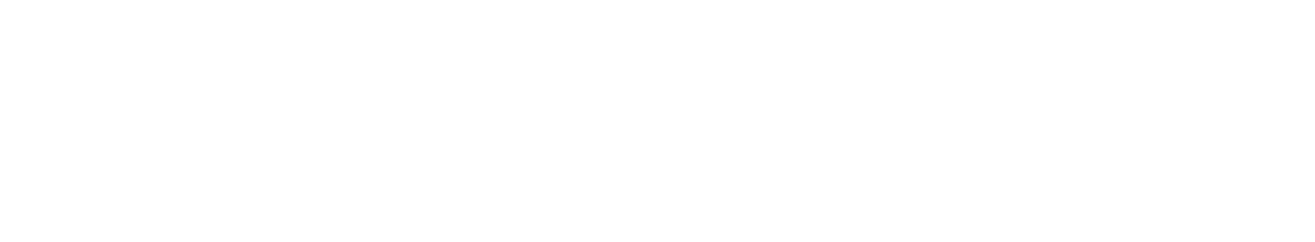

For most of human agricultural history, the food system was simple, a very localized production - consumption - recycle system.

Source: SB Hill (see Contributors)

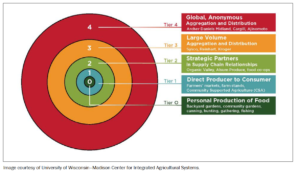

Now, it is highly complex, with billions of actors, trillions of transactions and multiply supply chain layers. Day-Farnsworth and Morales (2011) refer to the tiers of the food system:

Our current food system is dominated by particular concepts and values that guide decision-making among business people, farmers, scientists, politicians and bureaucrats and play a big role in determining how supply chains are organized. These concepts and values favour tiers 3 and 4.

High productivity, high inputs - High- and fast-yielding systems are considered paramount. Research focuses on: increasing crop yields per acre, the speed of crop development, animal growth rates and efficiency relative to feed intake, days of growth to get to slaughter weight, and the number of infants produced / animal. To obtain such results, large quantities of expensive inputs are used.

High volume, scale efficiency, low cost - Food businesses must have high 'throughput", high volumes of goods running through their operation. The businesses need to be large so that costs / item can be low. Low costs allow the business to charge less, which means more people will come buy the item which will increase the "throughput".

Shareholder value, dominate markets - To keep investors happy, corporations design their strategies to optimize shareholder value. As part of this strategy, they want to dominate markets, but not monopolize them, as that level of domination will trigger a government investigation of anti-competitive behaviour.

Centralization, distancing, export - Agribusiness firms and government officials believe that Canada must constantly grow its agricultural exports. They believe in "free trade" as an economic development strategy. Free trade is rooted in the idea that nations and firms can specialize, then centralize their production facilities in places where costs are low and scale efficiency high, and then distribute goods over long distances to reach all their markets.

Value-added to extract consumer dollar, homogenize taste - Value - added doesn't mean nutritional value, but rather extra expenditures by the consumer, increased willingness to pay more for a product. In this sense, value added translates to increased firm profitability.

Externalize costs – The food system generates many externalized costs for human and non-human health and the environment. These costs are not paid by the food system, but rather by other processes, such as health care and environmental cleanup. The food system has limited awareness of how it externalizes costs and with what awareness it does have, it expects those costs to be absorbed by other sectors of our society and economy. These costs do not show up in the price of food, and this process helps keep costs low.

Niches - Consumers interested in food quality, health promotion, organic and other food alternatives are all tolerated, sometimes encouraged by large food corporations, but only to a certain degree. The food system wants them to remain as places where some people can make money and some consumers can be satisfied, but such foods should not be allowed to grow beyond a certain stage because that would force widespread transformation of the existing model.

The simpler version of Canada's food supply chain is provided by AAFC (2015):

Given the number of food and beverage products and economic actors, the reality is far more complex, and the system is fundamentally unmanaged and unmanageable. Let's quickly look at a few supply chains:

Ontario Milk - Farmers milk their cows at least twice daily. The milk is then stored in big tanks, waiting for the dairy processor to pick it up with a large milk tanker truck (you've probably seen them on the highway). At that point, the milk is owned by the Dairy Farmers of Ontario, a supply management marketing board that determines how much milk farmers produce, what price they get for it and what prices milk processors pay (see Goal 2 Demand-Supply Coordination). The milk from the different farms gets pooled by the processor. Then it might get streamed to fresh milk (skim, 1%,2% or whole), or to additional processing for cheese, yoghurt, curds and other products. Some of it gets sold to food processors who make meals, like pizza. It gets shipped to food retailers, to restaurants, to cafeterias, daycares and homes for seniors. And, of course, it ends up in your fridge. You consume most of it, but on average, we waste almost 28% of the milk that comes out of a cow (Abdulla et al., 2013). Not only that, but our bodies can't use all the dairy we consume, so much of it is excreted and ends up in the sewage treatment system (the average Canadian drinks about a glass of milk per day and 2 slices of cheese, plus some yoghurt and other products). Very little milk is imported, but recent free trade agreements allow many countries to ship more cheese, milk proteins and other dairy products to Canada (see Goal 10 Free Trade).

Beef farms - They come in many sizes, from very small ones with a handful of cattle, to very large feedlots with thousands of animals. Many ranches cover tens of thousands of hectares; others, just a few hundred. The most typical is the cow-calf operation, usually part of a mixed farm with field crops. The number of such beef operations (and the number of cows) has been dropping however since 2010 according to Census of Agriculture data. In these operations, the cattle spend considerable time outdoors on pasture. Some live their entire lives on one farm, but most are moved (usually by truck) to other farms for different phases of their life, including being sold to farms in the US. Most end up in large feedlots for final finishing on corn and grain feed. For example, Alberta has some 150 feedlots and 38% of them have capacity for over 20,000 head. Then they are off to large slaughtering plants that can handle tens of thousands of animals each day. Beef is turned into numerous products, including hamburger, steak and prepared stews and soups. But since only about 55% of the animal is eaten by humans, the other 45% is rendered into industrial products, pet food and leather. About half our beef is exported, the other half consumed domestically. We also import beef products, particularly from the US. Beef consumption has been dropping, but many nutritionists think it should drop further for optimal health.

BC Eggs - Most egg farms are very large with thousands of laying hens in restricted living conditions. Each egg producer has a production quota, because eggs, like dairy, are also supply managed. Very small operations are usually allowed to produce eggs for their own consumption, but the way they sell eggs is restricted. Most egg operations buy their feed (usually combinations of wheat, corn, barley, rye , oats, flax and soy), so don't grow crops themselves and don't really have much of a land base as a result. Some of the egg producers are diversifying, producing free range, free run, omega oil enhanced or organic eggs and so segregate the birds in different barns. Eggs must be graded before being sold and most large operations have their own grading station. Those destined for the big retailers are shipped to their warehouses and then dispersed to stores. Other eggs go to processors to be added to baked goods and meal substitutes. Some are destined for the restaurant and cafeteria markets, often sold first to processors who crack the eggs and prepare large bags of liquid eggs for use in kitchens. As with dairy, imports are quite limited but increasing as free trade agreements require Canada to open up the supply managed sectors (also the situation for chicken and turkey).

Prairie Wheat - Canada is known for its wheat. It is one of our most planted crops and largest exports. Many varieties are grown and they have different end uses. Some are good for pasta (durum wheat), others for leavened loaves of bread, for pastry, crackers and flat breads. The lowest quality wheats (10-20% of the wheat crop depending on the year) go to animal feed and industrial uses such as fuel ethanol. Each kind of wheat has to be classified and handled distinctly because buyers don't want to get mixed batches as that creates complications at the processing stage. This means wheat has to be properly sorted coming off the field, to be cleaned and stored in separate bins, trucked or shipped by rail to larger elevators designated for that particular class of wheat and then moved to ships for overseas delivery - all without contamination. Buyers can reject a shipment if they receive a mixed batch. Canada does have a wheat milling and bakery processing sector, but most wheat exports are in raw, unprocessed form.

Prairie Canola - Canola is another of our main crops. Most varieties are genetically engineered (see Goal 4 Genetic Engineering). About 90% of the crop is exported, mostly in raw unprocessed form. It is used primarily for human oil, but because the oil processing stage produces a high protein crush, about 20% of the seed weight goes to animal feed, often dairy cows. Canola oil is now used also for biodiesel, plastics, cosmetics, lubricants, and paints.

Quebec Apples - Southeastern Quebec is one of the main apple growing regions in Canada (along with the Annapolis Valley of NS, Niagara in Ontario, and the Okanagan valley of BC). As with most fruit operations, apple farms tend to be small but have a high requirement for workers (mostly temporary foreign workers, see Goal 8 Labour Force Development), especially at harvest. About 70% of the apple crop goes to the fresh market and 30% to juice, cider, pies, apple sauce and other apple products. But there are only a small number of apple processors for farmers to sell to. Quebec has two large processors, three or four medium-sized ones, and 10 - 15 small buyers Fortunately for Quebec apple growers, they are members of the Apple Growers Federation of Quebec, which has some significant powers to negotiate prices. In other provinces, growers do not have such authority in the marketplace (sometimes they had it, but subsequently voted to abandon it). Canada was largely self - sufficient in apples for decades, but imports steadily increased after World War II and now Canada is a significant apple importer, mostly from the US. Fresh apple consumption is declining even though nutritionists urge us to eat more.

Strawberries - Most fresh strawberries are from the US and Mexico. The domestic strawberry sector is quite small, with a limited sales window in July and August. Some growers have been using varieties known as "day-neutral" that have a longer production window, and some are growing berries in greenhouses which also extends the season. Some local berries are processed into jams and pies The strawberry sector could be larger, but cheap imports and retailer distribution systems designed for long distance purchases make it difficult for small local growers to sell through the big grocery chains. As a result, some resort to pick-you-own and farmers markets sales. The import distribution chain is so sophisticated that California strawberries can be shipped by refrigerated truck and in Toronto homes within 2.5 days of harvest (Porter, 2009). This comes at a price as the system involves high levels of energy consumption and product waste.

ON Greenhouse vegetables - Southwestern Ontario is one of the main producing regions of Canada, with the main greenhouse vegetables being tomatoes, peppers and cucumber. The greenhouses are very energy intensive with significant capital investment required. Grown under glass, the growing season can be extended to 9-10 months annually, typically relying on soil - less hydroponic production techniques and biological pest control measures. Many of the workers are imported on a seasonal basis from Mexico and the Caribbean. About 70% of the vegetables are exported to the US, the rest destined for the domestic fresh market and sold mostly in supermarkets and restaurants. Production is regulated by the Ontario Greenhouse Vegetable Marketing Board. Paradoxically, Canada imports tomatoes from many of the same US states to which we export (probably qualifying as redundant trade).

PEI Potatoes - Potatoes are now grown primarily for the fresh market (with falling consumption rates) and processing (with rising consumption of french fries and potato chips). We produce more potatoes than we consume, so there are significant exports, particularly to the US (the bulk of it french fries, with some seed potatoes and table potatoes). Paradoxically, we also import potatoes despite being able to meet all our domestic requirements with existing production. PEI has the most potato farms and planted acres, though farm numbers have been declining for several years. About 2/3 of the crop goes for processing (AAFC. 2014). There are, however, only a small number of very large french fry and potato chip processors, so farmers don't have a lot of options on who they sell to.

A further complexity lies in Canada's dependence on import and export. Canada is the 5th largest importer in the world and also exports a lot (5th largest). Our main exports are live animals and meat products (mostly beef and pork), oilseeds and oilseed products (especially canola) and grain and grain products (especially wheat). We import those same broad categories of goods (which raises serious questions about the rationality of our imports and exports), many beverages, and fresh and processed fruits and vegetables. Many of our imports are things we grow, process and store domestically. For example, Ontario imports $10 billion more per year than it exports and by some estimates, half of that we could grow, process and store domestically (ERS et al., 2014).

Most of what we export is bulk or raw products or minimally processed. We export very few goods that have undergone significant processing, which means that we don't receive the economic benefits that are associated with selling more highly processed goods. Most of what we import is processed, so effectively we are paying for many things that we could process at home if we had better processing infrastructure and capacity. Our processing imports are rising more rapidly than our processing exports, so our balance of trade situation continues to decline and that creates problems for our food economy.

As briefly presented in the product snap shots above, analyzing food supply chains is made more complex by multiple end uses for crops and animals. Generally, there are human food, animal feed, and industrial uses, and how much of each crop or animal production system is devoted to these uses varies annually by region, weather, domestic and international supply chain and price and market dynamics.

For example, the main crops vary significantly in what is allocated to animal, human and industrial uses, and even within human food uses different product uses dominate (see table).

Table: Average breakdown of crop to main animal, human and industrial uses (gleaned from multiple sources, data from these sources is not always consistent)

| Crop | Animal | Human | Industrial |

| Barley | 78% | 20% malt for beverage industry | Straw increasingly used for fuel and building materials |

| Corn | 60% | 20% (syrup, starch) | 20% for fuel, inks, lubricants, soaps, paints, plastics and cosmetics. |

| Soybean | Crush by-product; feed-grade 15% | 65% crush oil

20% soy |

Some oil for fuel, inks, lubricants, soaps, paints, plastics and cosmetics. |

| Wheat | 10-20% | 80-90% | Straw increasingly used for fuel and building materials |